AI Use Cases in Logistics: Smart Supply Chain Solutions Transforming 2026

AI use cases in logistics are revolutionizing supply chains worldwide. The global AI in logistics market had exploded to $20.8 billion in 2025, representing a staggering 45.6% CAGR from 2020.

Companies implementing AI-powered logistics solutions report 78% experiencing significant operational improvements, while 67% of supply chain executives have fully or partially automated key processes using artificial intelligence.

Modern logistics faces unprecedented challenges. Customer expectations for same-day deliveries continue rising. Supply chain disruptions create volatility. Labor shortages affect operations. Rising costs squeeze margins. AI offers powerful solutions that transform these challenges into competitive advantages.

Early adopters gain measurable benefits. AI-powered supply chain management delivers 15% lower logistics costs than competitors while improving inventory levels by 35%. Companies save up to $300 million annually through AI-driven optimization and reduce carbon emissions by 1.5 million tons.

Route Optimization and Transportation Intelligence

Route optimization represents one of the most proven AI use cases in logistics. Traditional routing methods struggle with dynamic variables like traffic patterns, weather conditions, and delivery constraints. AI algorithms analyze hundreds of parameters in real-time to generate optimal routes.

Uber Freight pioneered algorithmic carrier pricing using machine learning. By analyzing hundreds of different parameters, they created accurate pricing models that eliminate friction and guesswork from trucking operations.

Real-World Impact:

- 25% reduction in delivery costs

- 40% faster shipment speeds

- 30% decrease in fuel consumption

- 50% improvement in on-time delivery rates

AI routing engines generate alternate scenarios faster than planners can evaluate manually. Transportation teams use AI to identify alternatives during disruptions rather than manually rebuilding plans. Humans still make final decisions, but AI reduces the time required to compare options.

Werner Enterprises uses GenLogs AI to reduce trailer location time from days to hours. The system enables Werner to identify unauthorized trailer use and settle claims with concrete proof. This translates to better resource allocation, reduced downtime, and enhanced operational control.

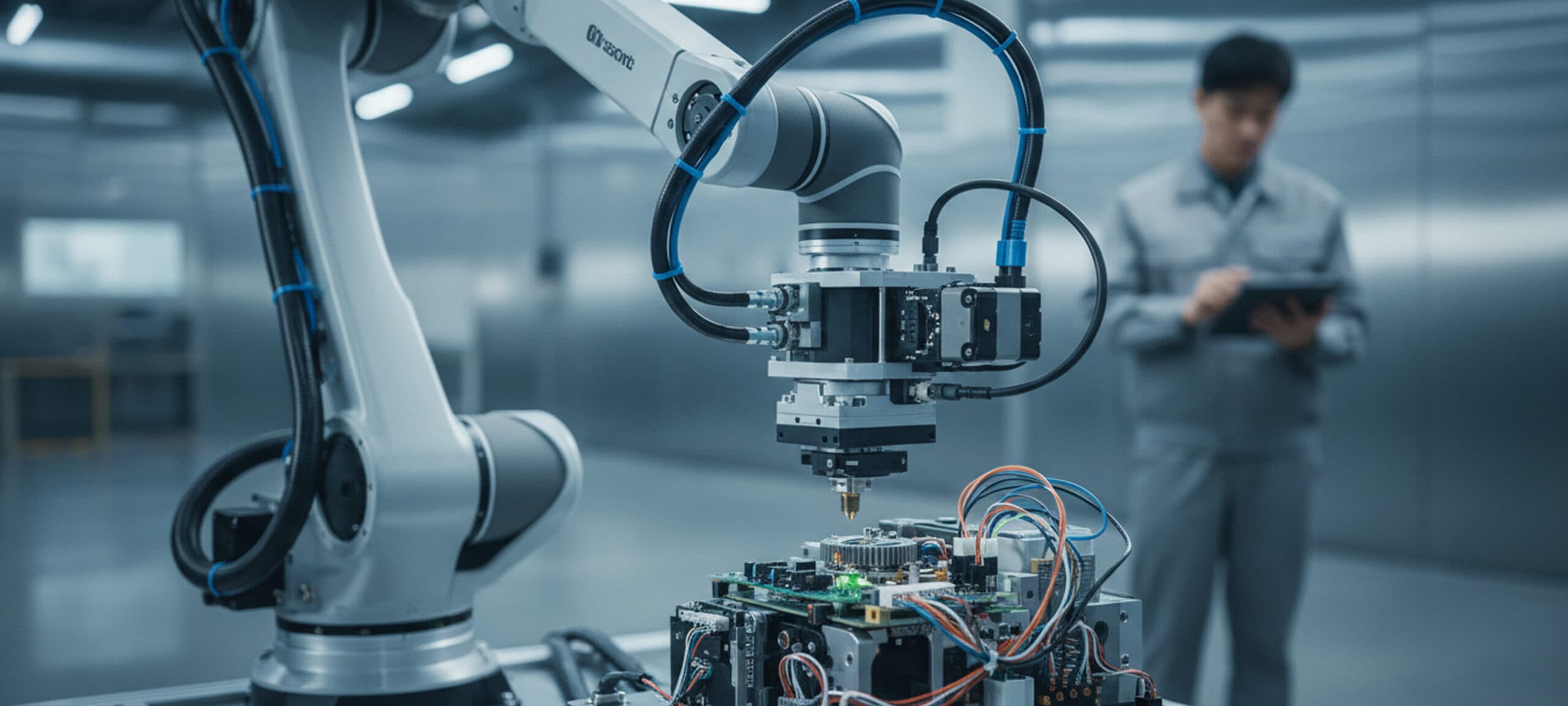

Intelligent Warehouse Automation

Warehouse automation showcases transformative AI use cases in logistics. The 2025 landscape demonstrates unprecedented adoption of AI-driven robotics within global distribution networks. One global retailer achieved 30% reduction in operational costs, 25% increase in order fulfillment speed, and 99.8% accuracy in inventory management.

Modern warehouses deploy Autonomous Mobile Robots (AMRs) that independently navigate floors to transport goods. Automated Storage and Retrieval Systems (AS/RS) use AI-powered robots to handle goods at scale with minimal errors. AI-guided robotic arms optimize picking processes by navigating efficient routes and reducing human error.

Key Technologies:

- Computer vision for inventory counting

- Predictive maintenance systems

- AI-powered conveyor networks

- Collaborative robots (cobots)

- Drone-based inventory tracking

Logistics provider GXO implemented AI-powered inventory counting that scans up to 10,000 pallets per hour. The system generates real-time inventory counts and insights while eliminating manual processes. IKEA uses robotic carousels to pack warehouse aisles with inventory, while Ocado’s automated “hive” moves bins with hundreds of mini-robots.

Demand Forecasting and Inventory Optimization

Accurate demand forecasting drives efficiency across entire supply chains. AI use cases in logistics excel at analyzing historical data, seasonal patterns, market trends, and external factors to predict future demand with unprecedented accuracy.

Southern Glazer’s leverages Amazon’s SageMaker AI solution for demand forecasting. Planners feed sales data, promotional events, and seasonality information into the system.

The AI generates forecasts considering historical data, current promotions, and seasonal variations. Artificial intelligence does well with long histories and databases.

Forecasting Capabilities:

- Real-time demand pattern analysis

- External signal integration (weather, events, economic indicators)

- Multi-location inventory balancing

- Automatic reorder point optimization

- Supplier lead time adjustments

The most reliable AI wins come from improving demand forecasts by integrating broader external signals. Companies move beyond historical sales curves to include weather data, social media sentiment, economic indicators, and local events. Retailers with large store networks see significant improvement when combining external signals with real-time store-level inventory visibility.

Predictive Maintenance and Asset Management

Equipment downtime costs logistics companies millions annually. AI-powered predictive maintenance represents critical AI use cases in logistics that prevent failures before they occur. Systems analyze sensor data, maintenance histories, and operational patterns to predict equipment problems.

Maersk implemented AI-driven Remote Container Management (RCM) systems transforming international shipping operations. The maritime logistics AI decreased vessel downtime by 30% through predictive maintenance, saving over $300 million annually while reducing carbon emissions by 1.5 million tons.

Maintenance Benefits:

- 50% reduction in unexpected breakdowns

- 25% decrease in maintenance costs

- 35% improvement in asset utilization

- Real-time equipment health monitoring

- Automated spare parts ordering

Edge AI enables sub-millisecond responses to changing conditions, critical for coordinating autonomous vehicles and robotics in dynamic environments. These systems continue functioning during connectivity disruptions, maintaining operational continuity despite challenging conditions.

Document Processing and Compliance Automation

Document-heavy workflows represent high-value AI use cases in logistics. Cross-border trade involves complex regulations that vary by lane and product. AI systems automate document classification, data extraction, and compliance verification.

One of the most valuable ROI areas is document processing. AI excels at extracting information and classification of documents. This use case can be applied to many parts of the supply chain and can significantly reduce manual processes while providing business value.

Document Automation:

- Invoice processing and verification

- Customs documentation management

- Bill of lading generation

- Regulatory compliance checking

- Contract analysis and extraction

RAG-enabled systems help teams navigate complex regulations while reducing manual review time and improving compliance accuracy. AI systems identify real exceptions sooner while filtering out routine processing noise. Document processing AI can reduce lead times by up to 60% while improving accuracy.

Real-Time Visibility and Exception Management

Supply chain visibility challenges multiply with global operations. AI use cases in logistics provide real-time tracking, anomaly detection, and proactive exception management across complex networks.

Visibility platforms using predictive ETA models and anomaly detection reduce noise by filtering false alarms and highlighting genuine issues. AI algorithms analyze transportation patterns, weather impacts, and historical performance to generate accurate arrival predictions.

Visibility Features:

- Multi-modal shipment tracking

- Proactive delay notifications

- Automatic rerouting recommendations

- Supplier performance monitoring

- Risk assessment and mitigation

Standard Logistics uses Optimal Dynamics’ Decision Automation Platform to optimize load acceptance decisions. The AI-based optimization engine determines which loads the fleet should accept and which to pass to brokerage solutions. This optimization improves asset utilization and profitability.

Customer Service and Communication Automation

Modern logistics requires constant communication with customers, suppliers, and partners. AI use cases in logistics automate routine inquiries while escalating complex issues to human agents.

Conversational AI handles order status inquiries, delivery updates, and basic problem resolution. Natural language processing understands customer intent and provides accurate responses across multiple channels including phone, chat, and email.

Communication Automation:

- Automated order status updates

- Proactive delivery notifications

- Multilingual customer support

- Supplier communication management

- Issue escalation protocols

AI-powered chatbots resolve 80% of routine inquiries instantly while reducing response times from hours to seconds. Integration with logistics systems provides real-time shipment information and delivery updates automatically.

Implementation Strategy for AI Use Cases in Logistics

Successful AI implementation requires strategic planning. Companies should start with smaller, well-defined operational bottlenecks where AI can reduce ambiguity, surface risks sooner, and compress decision cycles.

Best Practices:

- Identify high-impact, low-complexity use cases first

- Ensure data quality and system integration

- Plan for workforce training and change management

- Establish clear ROI metrics and timelines

- Scale gradually from pilot to full deployment

The most successful teams focus on specific problems rather than attempting rapid transformation across all operations. Document processing, demand forecasting, and route optimization typically deliver fastest returns on investment.

Measuring Success in AI Logistics Implementations

Quantifiable metrics demonstrate AI value in logistics operations. Leading companies track performance across multiple dimensions to validate investment returns and guide future expansion.

Key Performance Indicators:

- Cost reduction percentages (15-35% typical)

- Delivery time improvements (25-50% faster)

- Accuracy increases (95%+ in automated processes)

- Employee productivity gains (40-60% improvement)

- Customer satisfaction scores (20-30% increase)

Companies report saving $250,000+ annually from individual AI implementations with ROI achieved in less than 12 months. The technology has moved from experimental to mission-critical for competitive logistics operations.

Future-Proofing Logistics with AI Innovation

AI use cases in logistics continue expanding rapidly. Vendors shift from bolt-on copilots to AI-native workflows integrated directly into operational systems. Multi-agent systems handle complex coordination across supply chain functions automatically.

Graph RAG adoption expands from document retrieval to full knowledge-assisted reasoning. Teams use AI to evaluate cascading effects of disruptions and make faster mitigation decisions. Autonomous systems handle procurement cycles, vendor negotiations, and contract management with minimal human oversight.

The logistics industry transformation accelerates as AI accessibility improves. Cloud platforms, modular tools, and proven use cases make AI implementation possible for companies of all sizes. Those who start experimenting today position themselves to thrive as autonomous supply chains emerge.

Ready to Transform Your Logistics Operations?

These AI use cases in logistics represent proven pathways to operational excellence. Companies implementing AI-powered solutions gain competitive advantages through reduced costs, improved customer satisfaction, and enhanced operational resilience.

Isometrik AI provides intelligent automation solutions that streamline logistics workflows and optimize supply chain performance. Our conversational AI platform automates customer communications, supplier coordination, and exception management while integrating seamlessly with existing logistics systems.

Deploy AI-powered logistics automation in 6-8 weeks and join industry leaders already benefiting from intelligent supply chain management. The future of logistics runs on artificial intelligence.